Experience

Wellste Focus Researching,Developing and manufacturing on Aluminum Extrusion Industry more than 20 years

Custom Aluminum Extrusion Manufacturer

Over 20 Years Aluminum

Industry Experience

Advanced 35 Extrusion Presses Line

MOQ 500KG ONLY to boost your business

Loading Report Support for Each Shipment

Wellste Aluminum Extrusion Products

Extruded Aluminium Profiles

Aluminum Tubing

T-slotted Aluminum

Window & Door Profiles

Aluminum Heat sinks

Custom Aluminum Fabrication

How Wellste Control

The Quality of Your Aluminum Extrusion

Material Analysis

Guarantees your Aluminum Extrusions by 100% Pure A00 Aluminum Ingot

Mechanical Testing

Wellste In-house mechanical testing and certificate report for every shipment

Slat Spray Testing

Coating surface will randomly be selected by QC and passing salt spray testing

Cross-Cut Testing

Also called Paint Adhesion Testing, 100% inspection during the manufacturing process

About Us

OEM & ODM

Wellste have more than 30 rich-experienced Engineers whom are in Aluminum Industry, Wellste can custom your Aluminum Extrusions Also can design your own Products, Even If idea ONLY.

Manufacturing Capabilities

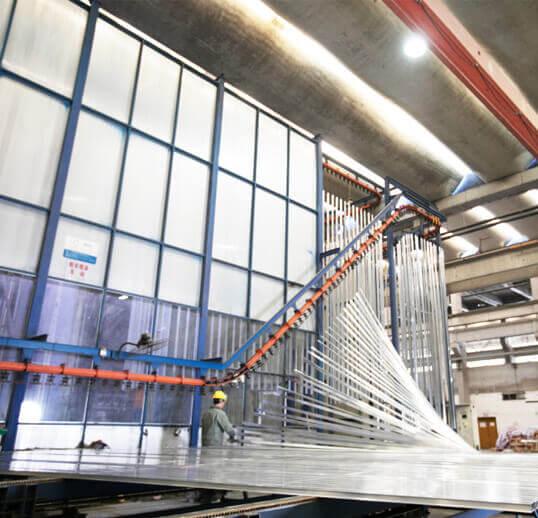

As an ISO9001-2001 certificated company, Wellste owns 35 Extrusion Lines, 5 Anodized Line, 5 Sprayed Production Line and 1 PVDF Production Line.

Aluminum Fabrication

Wellste integrates research, design, extrusion and deep machining service, such as cutting, CNC machining, bending, stamping, welding and more.

Aluminum Extrusion Manufacturing Capabilities

Mold Design

Aluminum Ingot Casting

Extruding press

Sandy Blasting

Anodizing

Spraying Coating

CNC Machining Services

Welding Service

Why Wellste is Trusted by 1000+ Clients

Wellste : To be your Premier

Aluminum Extrusion Supplier

Wellste technical staff is available 24/7 for support and fast response, giving full advice on your products and sharing engineering knowledge. Whether you order or not, we’re always here to support your business.

Anna Lau.

Sales Director

Two-shifts without any interval guarantees all orders and goods are delivered on time.

Tony Yan.

Factory Manager

Frequently Asked Questions

Wellste accepts many types of aluminum extrusion drawing files like DWG, DXF, PDF or IGS. Even if you have a rough sketch, our engineers will help in making drawings for free.

Considering heavy demand in construction and other industries, Wellste commonly produces 6000 series alloy, but if you have other special alloy numbers as like 3000 series, 5000 series or 7000 series, we can manufacture based on your requirements.

Contact us now to get a quick quote in 12H.

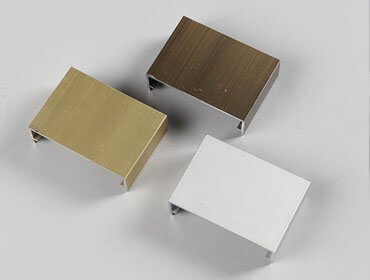

Wellste can produce various colors by anodizing. But most customers go for nature sliver, golden, bronze, and black colors.

Regarding powder coating, Wellste supports any kind of RAL No to match your special demands, or we can accept your color sample.

Wellste accepts 100% L/C and T/T generally. You can share with us your preferred mode of payments, and our sales team is open for discussion.

For long bar length aluminum extrusion, Wellste will separate all surface contact area using non-woven fabric, then wrap outside using composite paper.

For short, specific length aluminum extrusion parts, Wellste will separate them using non-woven fabric and then put into a carton box.

Wellste can supply your own custom packing and meet your special requirement.

Wellste owns tooling for more than 2,000 types standard aluminum extrusion profiles – from aluminum angle, aluminum rectangle bar, aluminum round bar, aluminum tubing, aluminum beam, and aluminum channel.

We can find 95% similar sectional size even if you’re describing the rough size from your end.

Product

- Extruded Aluminium Profile

- Aluminum Pipes & Tubes

- Window & Door Profile

- T slot Aluminum System

- Solar Mounting Structure

Capabilities

- Design

- Anodizing

- Powder Coating

- Aluminum Fabrication

- Assembly

Contact Us

- [email protected]

- +86-15951276160

- JiangYue Road Rd., Minhang Area, Shanghai, 212000 P.R.China

Latest Blog

- Aluminum Grades Unveiled: Selecting the Perfect Match for Your Project

- Understanding the Electrical Conductivity of Aluminum

- 6061 Aluminum Alloy – Decoding Properties and Uses, Etc